- REFRACTORIES DIVISION

- Eco-Friendly

Eco-Friendly

Most of refractories are designed to minimize hazardous material for workplace and environment. However, unlike from general living conditions, industrial conditions for refractory use may emit small amount of odor, hazardous fumes or gases due to higher temperature and stronger reactivity that would bring unfavorable effects in workplace and environment. Wonjin is doing its best everyday to develop and supply cleaner and safer eco-friendly refractory products to care more of health and safety for workers and to improve surrounding environment for better living condition.

Phenol Free LD Bricks

The most common products for ladle working lining bricks use phenolic resin as binder. Phenolic resin is very common material for various industries but emits unpleasant odors when decomposed in high temperature that may result workplace unfavorable. This is why demand for low phenol bonding system are increasing. Moreover, minor components or impurities in phenol emits hazardous gases which may affect one’s health in long term. Therefore, Wonjin promotes cleaner and healthier workplace by developing and supplying phenol free products.

Phenol Free Tundish Dry Vibratable

Wonjin was the first in Korea to develop tundish dry vibratable to make higher quality of steel with lower defect rate for steel industries. Today, Wonjin has removed phenol based binder to promote complete hazard free workplace while maintaining the performance of the product. Wonjin put continuous effort to supply and improve such new product to contribute in actualizing true eco-friendly workplace.

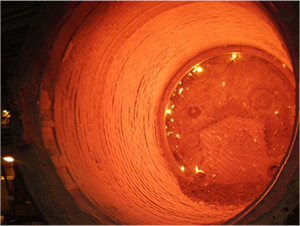

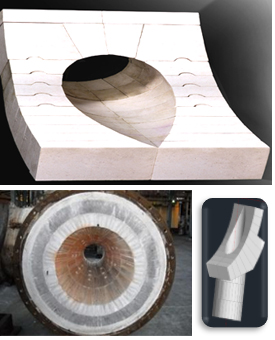

Cr-free RH Lining

RH degasser, one of secondary refining facility, use MgO-Cr2O3 working lining in the most places. Cr2O3 is not a hazardous material as it is, but has potential to transform into toxic hexavalent chromium at a specific condition, therefore more and more customers considering chrome free lining. Wonjin developed new MgO-C bricks with special graphite to replace MgO-Cr2O3 satisfying customer’s eco-friendly demand.

Cr-free refractory for Carbon Black reactor

The most popular refractory for carbon black reactor is Al2O3-Cr2O3 material as the condition reaches extreme temperature of 2,000℃. Although Al2O3-Cr2O3 refractory has best endurance at such temperature, also has possibility to transform to toxic hexavalent chromium, Wonjin developed and supply super high purity Al2O3 refractory product helping customers run reactors without worry of unwanted hazardous byproduct.